Collaborative Robots

Why Cobots Are a Game Changer for Die Casting

Pace has been an innovative company since its inception. It’s the basis of our corporate mission statement: provide uncommon, creative solutions, which contribute to the success of our customers. So it’s no wonder we’re leading the industry in technological advances, such as using collaborative robots on the manufacturing floor.

Collaborative robots, which are also called “cobots,” are designed in a way that allows a robot to physically interact with humans in a shared workspace. This differs from a conventional robot in that they don’t require a safety enclosure to operate. Cobots work at full-speed without jeopardizing safety.

Why are they used in manufacturing?

In addition to their safety features, Pace is interested in cobots because they’re affordable, highly adaptable and easy to use. Most of them operate from a smartphone or tablet, so they don’t require a high level of expertise to set up and program compared to conventional robots. This means they can be put into operation quickly and easily. And since they’re generally simpler than traditional robots, cobots are more affordable to maintain.

These robots are also highly efficient. When partnered with an associate, they produce an end result better and faster than either could do working alone. In fact, tasks that normally take days can be completed in a single shift.

How are they being used today?

Pace is still in the early stages of implementation. Right now we’re using them to perform repetitive operations, such as sanding of castings. We’re also using them in the process loading and unloading CNC machines. Having them in this capacity allows more time for a person to perform other value-added operations that require more skill.

Since they’re relatively lightweight, cobots can be moved from one work assignment to another. Because of this benefit, we’re looking at many other applications in die cast machine applications.

What’s the benefit to customers?

While there are multiple benefits to Pace, collaborative robots also benefit customers. They allow us to provide higher quality products while keeping costs in check. For example, when they’re programmed to work with CNC machinery, we can offer a more finished product. This eliminates having to send it out for additional steps in the process. Keeping everything in-house reduces costs and increases quality.

What does the future hold?

There will continue to be applications where it makes sense for associates to perform tasks manually. And some applications require overall automation to keep costs down and safety at a maximum. Cobots are proving to be the best solution for tasks that fall somewhere in between.

We believe there’s a growing need to integrate robots into the workforce to take advantage of the diverse strengths of both humans and robots. So Pace will continue to explore and implement more robots where they fit best in our processes. We’ll keep our focus on uncommon, creative solutions for the success of our customers – always.

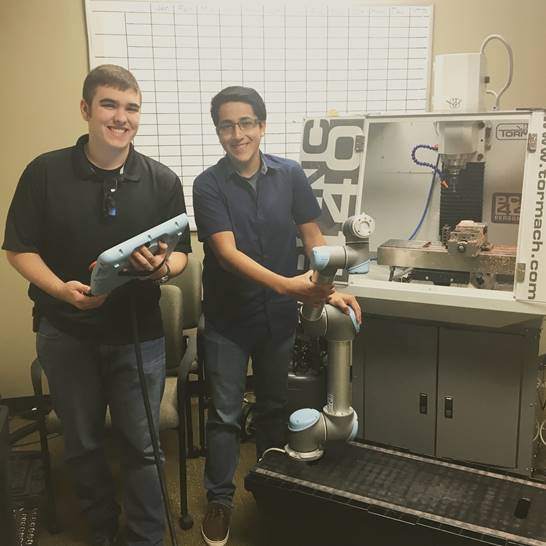

Juan Zuniga and Noah Wehn, both seniors at HarBer High School in Springdale and summer interns at Pace, used their skills to integrate a collaborative robot with a CNC machine.